I.Overview of Sublimation printing technology

Sublimation printing is a new type of printing process based on the sublimation characteristics of disperse dyestuffs. The core principle is to sublimate dyestuffs directly from solid state to gaseous state through high temperature (180-230℃), which penetrates into the interior of the synthetic fibers and solidifies. Since its industrialization in the 1970s, this technology has become the preferred printing method for polyester and polyester-spandex blended fabrics due to its environmental friendliness (no washing process, no wastewater discharge) and high-precision pattern expression.

The application in polyester fabrics is especially prominent, because its molecular structure in the high temperature gap expansion, to facilitate the penetration of dye molecules; and polyester-Spandex (polyester blends containing spandex) fabrics need to ensure that the polyester content of not less than 70%, in order to ensure that the dye is effectively absorbed. Compared with the traditional screen printing, Sublimation printing can realize 72 hours of continuous production, the speed can reach 2000-3000 m / h, and the pattern has a stronger sense of hierarchy, gradient effect of up to 256 color steps.

II.Processes and key technologies

1.Pre-treatment and material selection

Polyester-Spandex knitted fabrics need to be strictly boiled, shaped and sized to solve the problems of weft skew and rolled edges. The use of digital printing machine with penetrating agent can improve the smoothness of the fabric and reduce the color matching. The transfer paper is made in Holland with high temperature resistance and coated with silicone layer to enhance the efficiency of dye release.

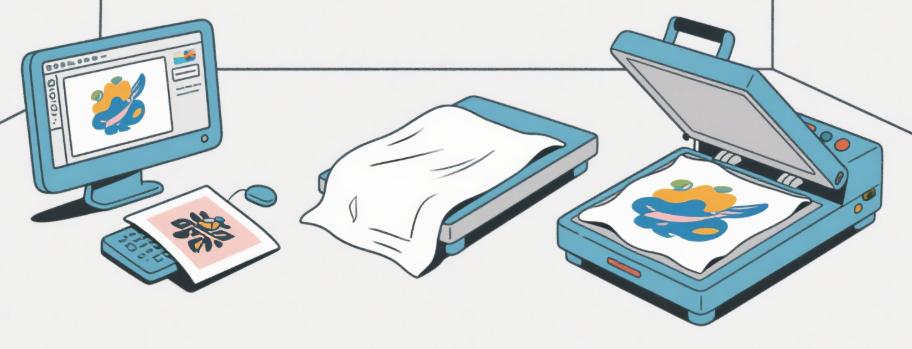

2.Digital design and printing

After completing the pattern design through CAD software, the 720dpi x 720dpi high-precision printhead is used to print the disperse dye ink onto the transfer paper. Attention should be paid to the mirror image design (horizontal flip) to adapt to the subsequent transfer direction, while controlling the ink viscosity in the range of 3-10mPa-s to prevent the printhead from clogging.

3.Heat press transfer process

The transfer temperature is usually set at 180-210℃, the pressure is controlled at 10-12kPa, and the time is adjusted to 20-45 seconds according to the fabric thickness. Vacuum negative pressure equipment (13.3kPa) can significantly improve the uniformity of dye penetration, especially for high elasticity polyester-spandex fabrics to avoid hardening of hand. Taking polyester-spandex fabrics as an example, high polyester content can be used with a combination of 180-210°C/30s parameters, while high elasticity sportswear requires a shorter time to prevent spandex damage.

4.Finishing and quality control

High temperature fixation (150-180℃/2min) is required after transferring to enhance the color fastness, and the rubbing fastness can reach 4-5 levels, and the washing fastness can reach 4 levels. The color difference ΔE value (<1.5) is detected by spectrophotometer, and the depth of penetration of dye molecules is analyzed by infrared spectroscopy to ensure the durability of the pattern.

III.Technical advantages and limitations

Advantages.

1. Environmental protection and high efficiency: no washing process, compared with the traditional printing water saving 95%, VOCs emissions reduced by 80%.

2. Color performance: 0.1mm ultra-fine lines and more than 90% color saturation, especially good at metallic luster, gradient halo and other complex effects.

Limitations:

Fiber Limitations:Natural fibers (such as cotton) have less than 30% color fixation, and more than 30% spandex in polyester-spandex blends will result in decreased color fastness.

Cost factors:The cost of transfer paper accounts for 35%-40% of the total cost of production, and the price of disperse dyes is 20% higher than reactive dyes.

IV.Innovative application scenarios

For its Spring/Summer 2025 collection, Italian brand La Perla uses heat sublimation technology to reproduce Monet’s Water Lilies in a polyester-ammonia swimsuit (78% polyester + 22% spandex), which is precisely temperature-controlled at 230°C/28s, so that the pattern retains 95% of its color retention after 10 seawater immersions.

If you’re also looking for high quality swimwear fabric for sublimation print, please check below our product link:

V. Future development trends

1. Green process upgrading

Carbon emissions can be reduced by 42% with bio-based disperse dyes (such as Clariant’s Vat Eden range) and recycled polyester fibers. The EU plans to introduce tariff preferences for heat sublimation printed fabrics containing more than 30% recycled polyester from 2026.

Fuzhou Huasheng Textile are currently GRS certified to support recycled polyester materials. We have always been committed to environmentally sustainable business practices and see this not only as a trend, but as the inevitable future direction of the industry.

Conclusion

Polyester/polyester-spandex knitted fabric sublimation printing technology is reshaping the textile printing and dyeing industry with the characteristics of “precision, efficiency and sustainability”. With the digital, functional technology, the depth of integration, the process will show greater potential in the field of smart wear, medical textiles, etc., to promote the “textile + technology” industrial revolution. Enterprises need to focus on the intelligent transformation of equipment, research and development of environmentally friendly materials and cross-field technology grafting, in order to take the lead in the global industrial upgrading.

Fuzhou Huasheng Textile has rich experience in sublimation fabric production, research and development, dedicated to providing high quality polyester/polyester spandex knitted sublimation fabric. Here are some links of our fabrics suitable for sublimation sports uniforms.

1. Polyester fabric:

https://www.fuzhoutextile.com/polyester-interlock-quick-dry-bird-eye-mesh-fabric-for-sport-tops-product/

https://www.fuzhoutextile.com/moisture-wicking-polyester-football-mesh-fabric-for-sportswear-product/

https://www.fuzhoutextile.com/polyester-micro-mesh-moisture-wicking-fabric-for-sports-shirts-product/

https://www.fuzhoutextile.com/100-polyester-white-pique-knitted-fabric-for-garment-product/

https://www.fuzhoutextile.com/competitive-price-100-polyester-knitted-interlock-lining-fabric-product/

2. Polyester-spandex fabric:

https://www.fuzhoutextile.com/polyester-spandex-stretch-jacquard-knitted-mesh-fabric-for-sports-wear-product/

https://www.fuzhoutextile.com/95-polyester-5-spandex-single-jersey-knitted-fabric-product/

https://www.fuzhoutextile.com/polyester-spandex-jacquard-knitting-mesh-fabric-for-lining-product/

https://www.fuzhoutextile.com/polyester-spandex-waffle-jacquard-mesh-stretch-fabric-product/

https://www.fuzhoutextile.com/83-polyester-17-spandex-jacquard-knitted-mesh-fabric-for-sports-shirt-product/

Post time: May-21-2025