Color fastness, also known as colour fastness, refers to the resistance of dyed or printed textiles to color changes or fading when exposed to various external factors like washing, light, sweat, or rubbing. In the textile industry, understanding **what is color fastness** is crucial for ensuring high-quality fabrics that maintain their vibrant appearance over time. This property measures how well dyes adhere to fibers, preventing bleeding, staining, or discoloration. Whether you’re a consumer shopping for durable clothing or a manufacturer aiming for superior products, color fastness plays a key role in textile performance and longevity.

In this guide, we’ll explore the definition of color fastness, its importance, common types, measurement methods, and tips for improving it in fabrics like knitted materials. By optimizing for factors like wash fastness and light fastness, you can select or produce textiles that stand the test of time.

Why Is Color Fastness Important in Textiles?

Durability and Longevity: Fabrics with excellent color fastness withstand repeated washing, wear, and environmental exposure without losing their original hue. This is especially important for everyday items like clothing, upholstery, and home textiles..

Prevention of Staining and Bleeding: Low color fastness can cause dyes to transfer during laundering, leading to stains on other garments or surfaces. This is a common issue in mixed loads of laundry, where dark colors might bleed onto lighter ones.

Quality assurance and Market Vale: Textiles with superior color fastness meet industry standards and certifications, enhancing their perceived value. For businesses, this translates to fewer returns, positive reviews, and compliance with regulations like ISO or AATCC standards.

Investing in high-color-fastness materials not only improves user experience but also supports sustainable practices by reducing the need for frequent replacements.

Common Types of Color Fastness Tests

Color fastness isn’t a one-size-fits-all concept; it encompasses several specific resistances tailored to real-world scenarios. Below are the most common types, each evaluated through standardized testing:

Wash Fastness: This tests how well dyes hold up during laundering. It simulates repeated washing cycles to check for fading or color migration to adjacent fabrics. Ideal for apparel and bedding.

Rubbing Fastness (Crocking): Measures resistance to color transfer from friction, both in dry and wet conditions. It’s essential for items like jeans or towels that experience regular contact.

Light Fastness: Evaluates fading due to sunlight or artificial light exposure. Crucial for outdoor fabrics, curtains, or automotive interiors where UV rays can cause degradation.

Sweat Fastness: Assesses how dyes react to human perspiration, which contains salts and acids. This is particularly relevant for sportswear and activewear.

Other types include perspiration fastness (a variant of sweat), water fastness, and chlorine fastness for swimwear. Understanding these helps in selecting the right fabrics for specific applications.

How Is Color Fastness Measured and Tested?

Color fastness testing follows international standards like those from the American Association of Textile Chemists and Colorists (AATCC) or the International Organization for Standardization (ISO). These methods use specialized equipment to simulate environmental stresses and quantify results objectively.

Key Measurement Tools and Methods:

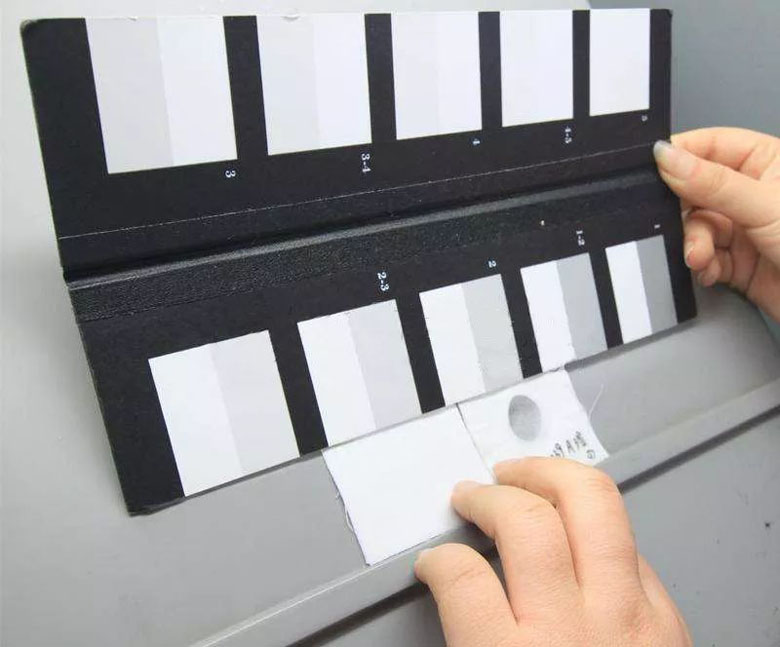

Grey Scale Assessment: A standard grey scale card is used to visually compare color changes. It ranges from 1 (significant change) to 5 (no change), providing a quick, reliable rating for fading or staining.

Rating System: Most tests employ a 1-5 scale, where 5 indicates excellent fastness (minimal color loss) and 1 signifies poor performance (severe fading). Some advanced tests use a 1-8 scale for light fastness.

Textile Testing Machines: Equipment like launderometers (for washing), crockmeters (for rubbing), and xenon arc lamps (for light) replicate real conditions. Samples are exposed, then evaluated for color retention using spectrophotometers for precise measurements.

To achieve accurate results, tests are conducted under controlled conditions, often in certified labs. Factors like fabric type (e.g., cotton vs. polyester) and dye chemistry influence outcomes.

Tips for Improving Color Fastness in Knitted Fabrics

For knitted fabrics, which are prone to stretching and dye absorption issues, enhancing color fastness involves careful selection of dyes and processes:

- Use reactive or vat dyes for better bonding with fibers.

- Apply fixation treatments during dyeing to lock in colors.

- Follow care instructions, like cold washing and air drying, to maintain fastness.

- Opt for pre-tested fabrics from reputable suppliers.

If you’re dealing with custom knitting projects, consulting experts can help tailor solutions to your needs.

Frequently Asked Questions (FAQs) About Color Fastness

What factors affect color fastness?

Fabric composition, dye type, manufacturing processes, and environmental exposures all play roles. Natural fibers like cotton may have different fastness levels compared to synthetics.

How can I test color fastness at home?

Simple tests include rubbing a wet cloth on the fabric or exposing a sample to sunlight, but professional lab testing is recommended for accuracy.

Is color fastness the same as colorfast?

Yes, “colorfast” is often used interchangeably with high color fastness, meaning the color won’t fade easily.

Conclusion

Mastering “what is color fastness” empowers you to make informed decisions in textile selection and production. High fastness ensures vibrant, long-lasting fabrics that meet consumer expectations and industry standards. If you’re seeking premium knitted fabrics with superior color fastness or need expert advice, contact us today for tailored solutions.

Tips for Improving Color Fastness in Knitted Fabrics

For knitted fabrics, which are prone to stretching and dye absorption issues, enhancing color fastness involves careful selection of dyes and processes:

- Use reactive or vat dyes for better bonding with fibers.

- Apply fixation treatments during dyeing to lock in colors.

- Follow care instructions, like cold washing and air drying, to maintain fastness.

- Opt for pre-tested fabrics from reputable suppliers.

If you’re dealing with custom knitting projects, consulting experts can help tailor solutions to your needs.

Frequently Asked Questions (FAQs) About Color Fastness

What factors affect color fastness?

Fabric composition, dye type, manufacturing processes, and environmental exposures all play roles. Natural fibers like cotton may have different fastness levels compared to synthetics.

How can I test color fastness at home?

Simple tests include rubbing a wet cloth on the fabric or exposing a sample to sunlight, but professional lab testing is recommended for accuracy.

Is color fastness the same as colorfast?

Yes, “colorfast” is often used interchangeably with high color fastness, meaning the color won’t fade easily.

Conclusion

Mastering “what is color fastness” empowers you to make informed decisions in textile selection and production. High fastness ensures vibrant, long-lasting fabrics that meet consumer expectations and industry standards. If you’re seeking premium knitted fabrics with superior color fastness or need expert advice, contact us today for tailored solutions.

Post time: Sep-30-2025